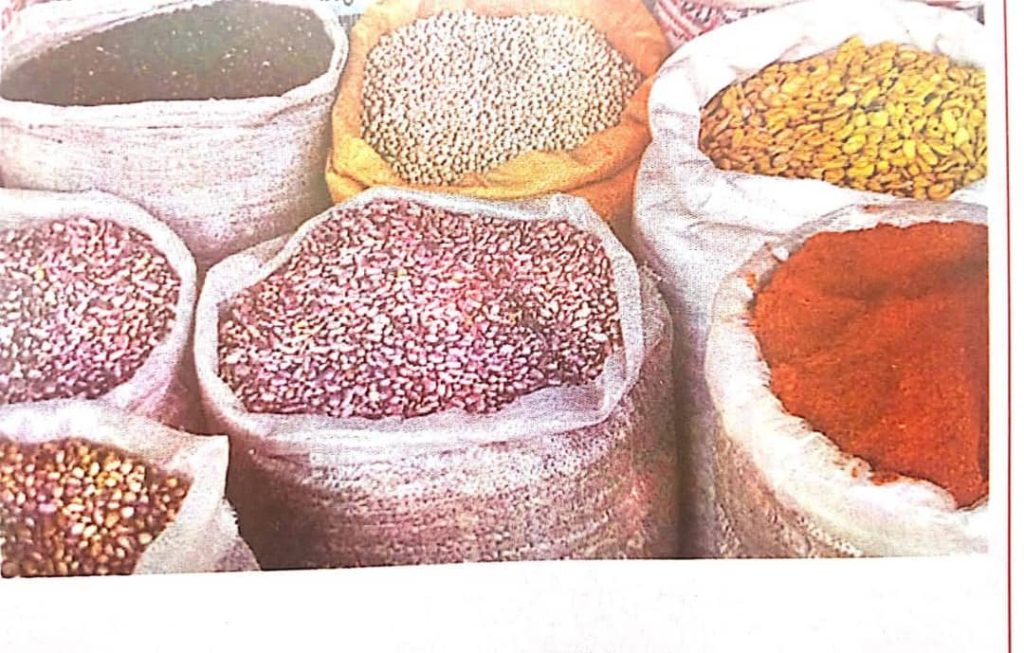

Atim is a market vendor in your community. She deals in buying. Stocking and selling agricultural produce.

She has been complaining that farmers mix some metals into the produce to make it.

Write an advice note explaining how she can detect and remove the metallic materials out of the produce.

NLSC. Chemistry-Engaging Assignments for the New Lower Secondary Curriculum Assignment 1: Chemical Bonding Scenario: You…

4(a) what are your roles as citizen of Uganda? (b) Each and every individual in…

3(a) why do we political Eduction in the New Uganda curriculum? (b) Explain the roles…

View Comments

dear mrs atim

As a student of physics specializing in magnets and magnetic fields, I've learned about a practical application that could greatly assist you in improving the quality of your produce: detecting and removing metallic materials.

Metallic materials such as nails, screws, or other small metal objects can accidentally find their way into your produce during various stages of cultivation and processing. Not only can these materials be hazardous to consumers, but they can also damage processing equipment and reduce the overall quality of your harvest.

Here's a simple yet effective method you can use to detect and remove metallic materials from your produce:

By implementing these measures, you can significantly reduce the risk of metallic contamination in your produce and uphold high-quality standards for your farm. Remember, the safety and satisfaction of your customers depend on the care and attention you put into ensuring the purity of your harvest.

dear mrs atim

As a student of physics specializing in magnets and magnetic fields, I've learned about a practical application that could greatly assist you in improving the quality of your produce: detecting and removing metallic materials.

Metallic materials such as nails, screws, or other small metal objects can accidentally find their way into your produce during various stages of cultivation and processing. Not only can these materials be hazardous to consumers, but they can also damage processing equipment and reduce the overall quality of your harvest.

Here's a simple yet effective method you can use to detect and remove metallic materials from your produce:

By implementing these measures, you can significantly reduce the risk of metallic contamination in your produce and uphold high-quality standards for your farm. Remember, the safety and satisfaction of your customers depend on the care and attention you put into ensuring the purity of your harvest.